What are the steps for the processing of luxury bags?

Let’s see what are the stages for the processing of luxury bags and how they are made by the hands of skilled craftsmen.

Luxury bags processing: the first step

Before talking about the processing of luxury bags in detail we need to start from the beginning.

Therefore, what is the first step of every project? The idea.

This is the first step not only for the processing of a luxury bag but also for every single project.

My idea was born looking outside at a Venice palace, where I was searching for the history of fabrics and old fashions.

But suddenly the passage of a gondola caught my attention, and that is how Eliem was born.

And remember that when you have an idea in your mind it is important then to find a manufacturer who helps you to improve your project and choose the most appropriate materials for your needs.

An expert will help you to choose the best accessories and make your idea a real final product.

The planning and design of bag models

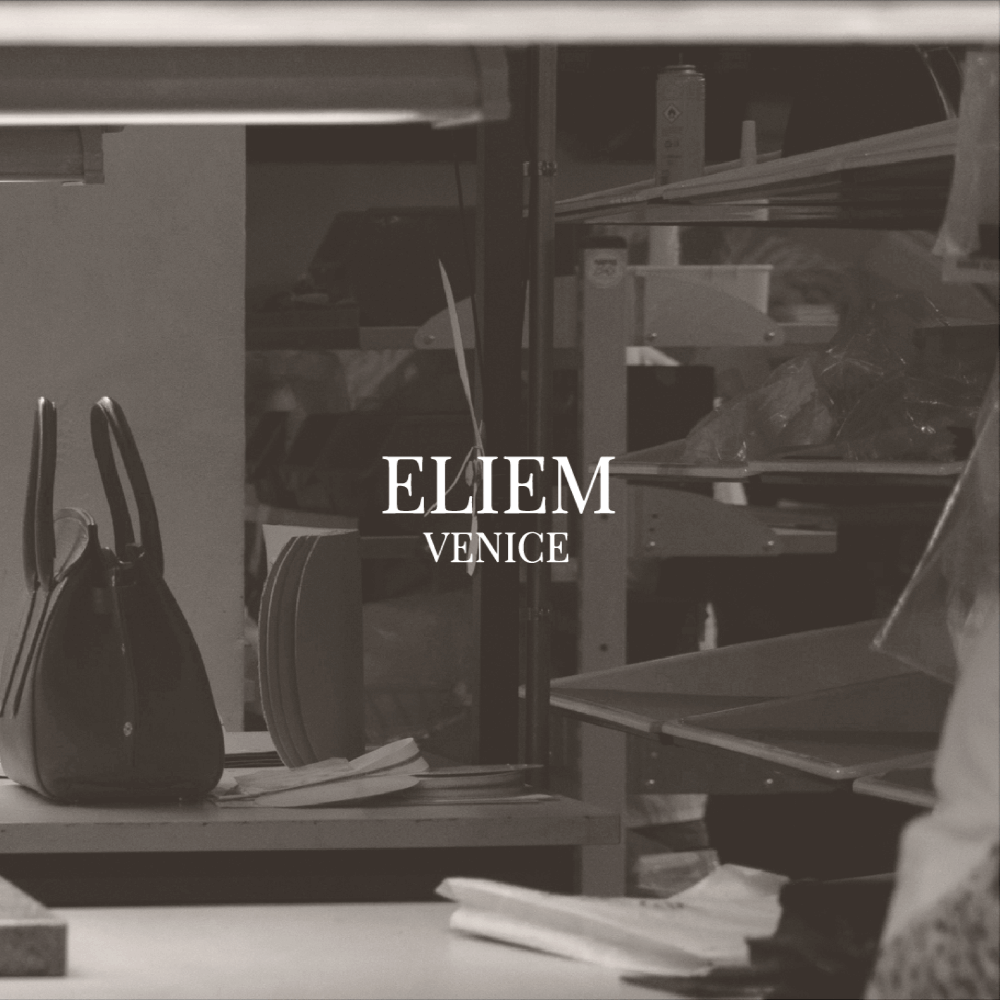

One of the first things craftsmen make before the processing of luxury bags is the planning of products and the design of single models.

Every collection shows specific needs, from different ideas to different messages to be transmitted.

To make every single model at best the craftsman has to know all of the details.

First of all, he makes a design that matches the base, then he does sampling and, in the end, he makes the prototypes.

I did a lot of them also for Eliem, choosing then the company that reflected at best my needs and the craftsmanship that I was looking for.

Luxury bags processing: the cut of the leather

Once craftsmen defined and made prototypes at the laboratory, they do the cut of the leather.

We are talking about one of the most difficult phases of luxury bag processing.

It is important to have a steady and expert hand for getting a final excellent result.

Usually, the cut on the parts of hides is handmade but often it’s made automatically in large-scale production where products are reproduced in large volumes.

The shaping phase

And now two important phases of the luxury bags processing take place: the reduction and the flashing.

Every single model of Eliem is composed of different parts that have to be prepared for being then assembled and give birth to the real bag.

Then the pieces of leather are thinned to have the right thickness and be worked.

Because not all of the hides have the same thickness, the passage of the reduction has to be done very carefully.

And after this process, it is time to do the flashing, to smooth the edges of the bag before all the pieces are sticked or stitched together.

The product begins to take shape: The sticked and refinement phase

Now we start to see our product take shape (I was very excited when I saw the first prototypes of Eliem).

And this is the phase in which edges of bag pieces are sticked together.

Then margins are trimmed in order to have the same shape perfectly.

By doing this, the product starts to be real and not just an idea anymore, becoming more and more a final product.

The hands of craftsmen whom I trust for making every part of Eliem’s bag check the smallest imperfections in order to create a perfect product in every single detail.

For example, the care and attention of details are even more evident in the Agata bag, which, with its reversibility, is made in detail both inside and outside.

Once the sticked phase end, it is time for the stitching ones and the implementation of accessories that, if made by the hand of expert craftsmen, can really make the difference.

But be careful: one single mistake can ruin the whole work.

There are a lot of working hours that separate the original idea from the product that you hold in your hands.

Eliem’s products, made by expert craftsmen from Venice, are unique and elegant and are models that talk about Italian creativity and innovation.